RC300 Handheld box

RC Robot Arm Series Controller

Based on the embedded industrial control platform, RC300 adopts graphical programming design, dialog-box interface, which is easy to understand and operate. And it can be flexibly applied with subprograms such as stacking, returning to standby, and quick placement, so as to meet complex machining demands. Meanwhile. it can be configured with various servo motors to take out products quickly, and achieve precise positioning. As a result, it offers a complete set of perfect solutions for machine tools with robots.

Characteristics

- • Instructional programming for easier operation.

- • Automatic detection of faults, safer and more secure.

- • Friendly and customizable user interface and encryption time management.

- • Easy to understand PLC logic control.

- • Humanized design and better portability.

Specification parameters

RC300

Item

Specification

Standard control axis number

Five pulse axes

CPU

Cortex-A8,DDR3 512MB

Storage space

512MB

LAN

1*100Mbps

Display size

7-inch, 800*480 resolution

Industry application

Lathe robot, magnetic tile machine, injection molding machine

Programming language

Teaching programming

Embedded program function

Stacking, sampling, placement of defective products, return to standby, fast to placement

Mold

It can store 6000 groups

Main program

500 steps

Subroutine

100 subroutines, subroutine step unlimited

Intelligent management function

Five levels of passwords can be set

QC function

Sample capture, quality management

Maintenance function

Customizable maintenance plan

Fault detection function

Automatically detect faults and record fault content

PLC function

Robot combined with PLC

Backup & Update Function

One-click backup & update Via USB flash drive

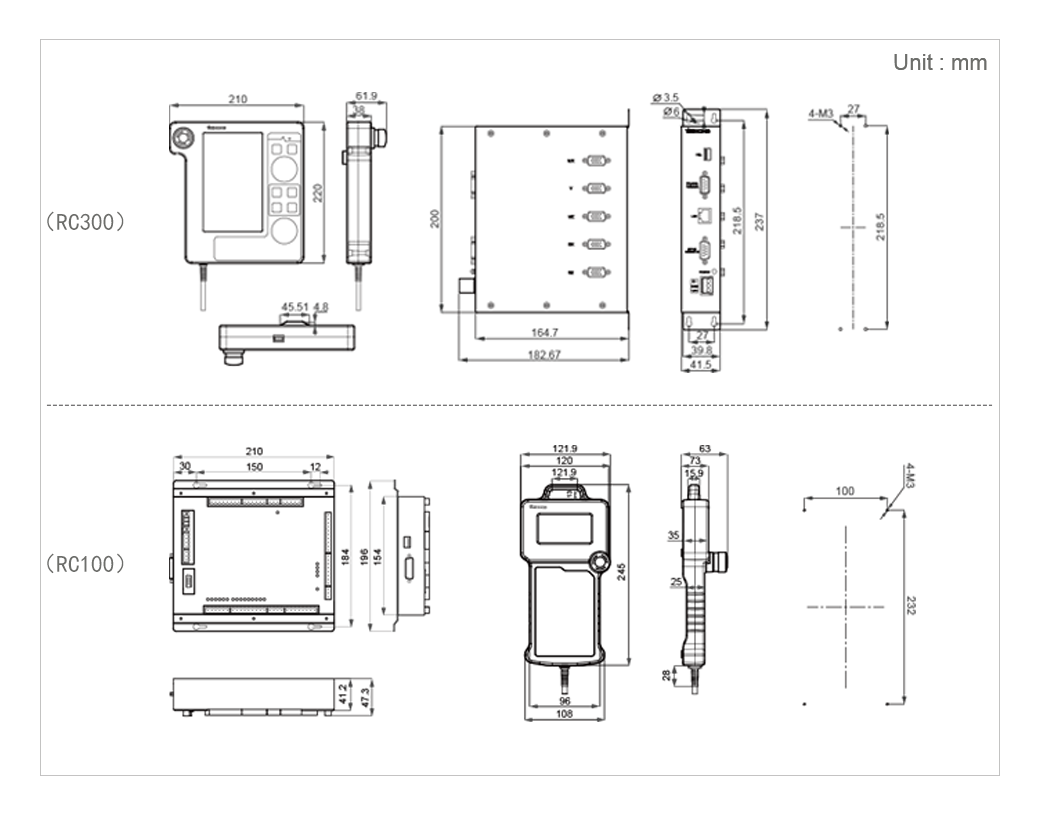

Mounting Dimension

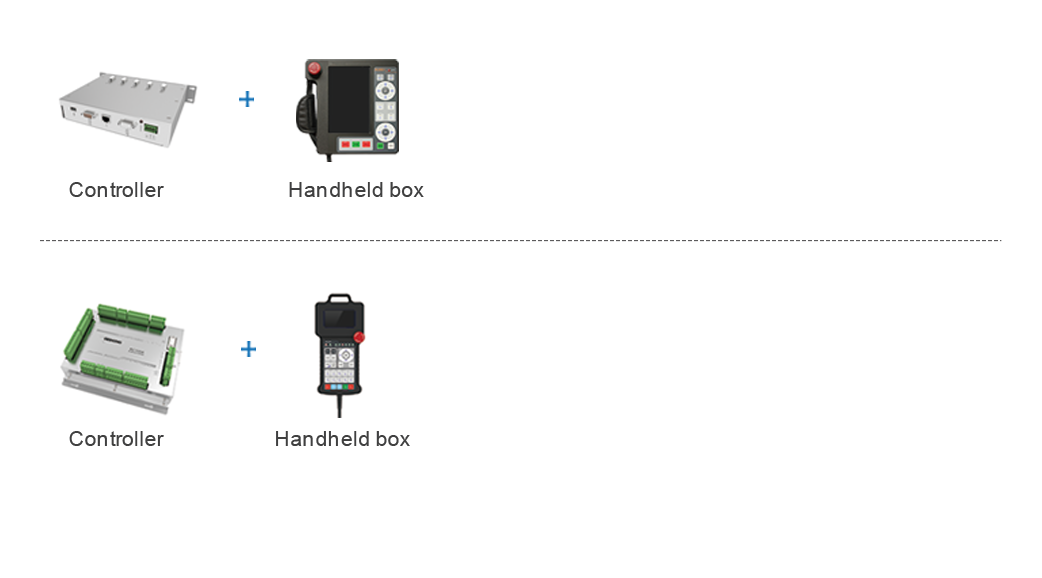

Product Configuration

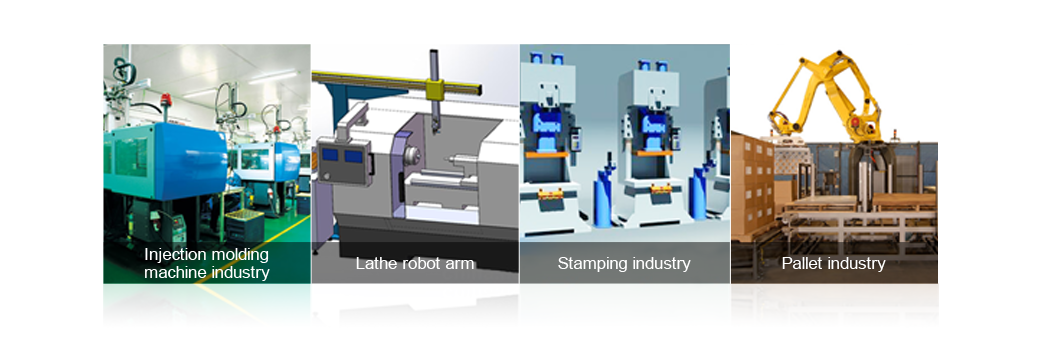

Application