Waterjet Cutting

It has been widely applied in cutting metal, stone, glass, ceramic, etc.

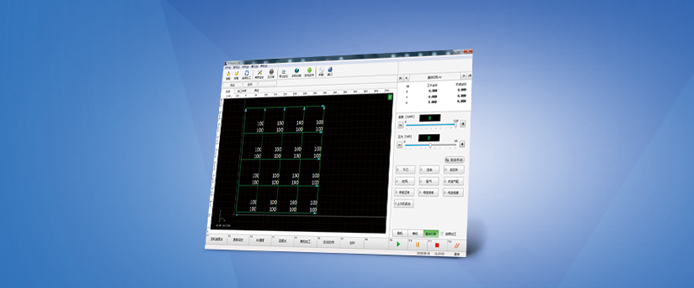

The system covers motion control solutions over 2~5 axes, among which five-axis waterjet cutting CNC system, is the earliest and most mature system in domestic market. It can achieve dynamic five-axis cutting and solve the tapper and trailing problems of high-pressure waterjet technology.

Glass Cutting

It has been widely applied in machining glasses for different uses, e.g. architecture, home appliance, photoelectricity, PV, mobile phone, glass splicing, etc.

The system boasts leading functions such as following normal line of the rotary-axis, eccentricity compensation, precise cutting pressure control by analog quantity.